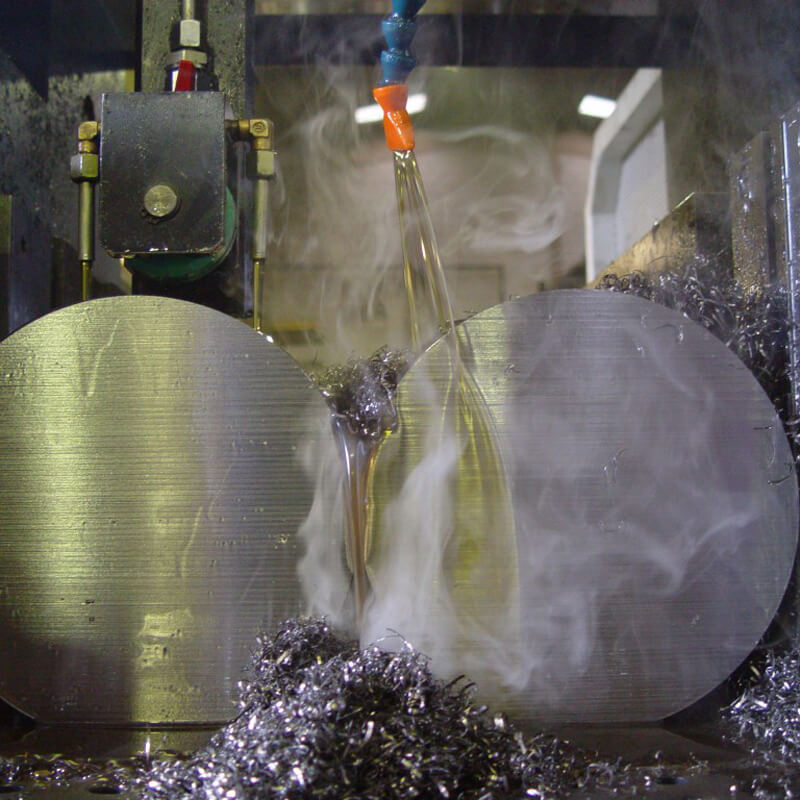

Stamping and cutting sheet metal and blank is a metal-forming procedure that allows production of parts with complex shapes. The use of new materials (HLE steel, ferritic stainless steel, aluminium) associated with increasingly important environmental constraints and cost reductions requires the use of high-performance lubricants.

Drawing on our technical expertise and our know-how in the field of cold metal-forming, we offer the Condaform range intended for cutting and stamping of metals.

Taking the HSE impact into account is an integral part of the technical specifications for our lubricants. CONDAT therefore offers alternative technologies and draws on bio-sourced raw materials.

Globe Condaform CEV-2000 is a light-duty, chlorine-free, metalforming lubricant designed for forming aluminum and other soft metals. The evaporative properties of Globe Condaform CEV-2000 greatly reduce lubricant residue on formed parts and eliminate the need for post-cleaning operations. Globe Condaform CEV-2000 can be used in numerous metalforming operations. Globe Condaform CEV-2000 is ideally suited for fin stamping in the HVACR market.

Globe Condaform CEV-1332 is an evanescent, chlorine-free lubricant, designed for cold deformation.